The best beer I've ever tasted was in a little brew pub in Homburg, Germany (not Hamburg, Homburg). It was malty without being sweet, subtly hoppy (maybe dry hopped), and moderately full-bodied. I've been told that much that I liked was probably due to decoction mashing. I've tried decoction mashing a few times and have not been impressed with the results. I suspect the less than impressive results are due to my difficulty hitting the rest temperatures during each decoction.

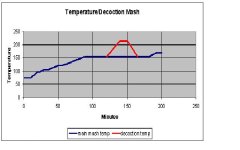

So, I've been trying to come up with a way to hit my rest temperatures accurately and get the benefits of decoction. My plan is to use my HERMS setup to raise the mash to saccrification, pull out most of the grain and boil it, cool it to the saccrification temperature and return it to the mash tun to complete saccrification of the decoction.

Here are my steps:

Dough-In: 10 pounds less modified Pilsner malt, .75 pounds Munich malt, .25 pounds melanoid malt, 22 qts water. Let sit for ten minutes to absorb water and settle the grain bed

Acid Rest: heat to 100 degrees F. Hold for 10 minutes

Protein Rest: heat to 122 degrees F. Hold for 10 minutes

Saccrification I: heat to 153 degrees F. Hold for 20 minutes

Decoction: remove most of the grain with sufficient wort to cover. Boil grain for 15 minutes. Cool to about 154 degrees by adding about10 qts water and using immersion chiller. Return to main mash.

Saccrification II: hold at 154 degrees for 30 minutes.

Mash-out: raise to 168 degrees F

Run-off

My rationale is that most of the wort - with most of the enzymes - will be held at about 153 degrees F for about an hour-and-a-half. Hopefully, the dilute wort will prevent excessive conversion that could produce a thin beer. Hopefully, the boiling of the grain will give most of the benefits of multiple decoctions without the difficulties of holding at conversion temps.

Questions:

1. I'm using Jamil Z's recipe for Munich Helles (Jamil Zainasheff;John Palmer. Brewing Classic Styles: 80 Winning Recipes Anyone Can Brew (p. 53). Kindle Edition), which calls for 4 oz Melanoid malt to provide the melanoidin typically produced by decoction. Should I omit the melanoid malt?

2. Will the single decoction at the end of the mash give the same benefits as multiple decoctions throughout the mash?

3. Any suggestions?

Dan

So, I've been trying to come up with a way to hit my rest temperatures accurately and get the benefits of decoction. My plan is to use my HERMS setup to raise the mash to saccrification, pull out most of the grain and boil it, cool it to the saccrification temperature and return it to the mash tun to complete saccrification of the decoction.

Here are my steps:

Dough-In: 10 pounds less modified Pilsner malt, .75 pounds Munich malt, .25 pounds melanoid malt, 22 qts water. Let sit for ten minutes to absorb water and settle the grain bed

Acid Rest: heat to 100 degrees F. Hold for 10 minutes

Protein Rest: heat to 122 degrees F. Hold for 10 minutes

Saccrification I: heat to 153 degrees F. Hold for 20 minutes

Decoction: remove most of the grain with sufficient wort to cover. Boil grain for 15 minutes. Cool to about 154 degrees by adding about10 qts water and using immersion chiller. Return to main mash.

Saccrification II: hold at 154 degrees for 30 minutes.

Mash-out: raise to 168 degrees F

Run-off

My rationale is that most of the wort - with most of the enzymes - will be held at about 153 degrees F for about an hour-and-a-half. Hopefully, the dilute wort will prevent excessive conversion that could produce a thin beer. Hopefully, the boiling of the grain will give most of the benefits of multiple decoctions without the difficulties of holding at conversion temps.

Questions:

1. I'm using Jamil Z's recipe for Munich Helles (Jamil Zainasheff;John Palmer. Brewing Classic Styles: 80 Winning Recipes Anyone Can Brew (p. 53). Kindle Edition), which calls for 4 oz Melanoid malt to provide the melanoidin typically produced by decoction. Should I omit the melanoid malt?

2. Will the single decoction at the end of the mash give the same benefits as multiple decoctions throughout the mash?

3. Any suggestions?

Dan