Beta B4 Alpha

Apprentice

- Joined

- Mar 19, 2022

- Messages

- 7

- Reaction score

- 0

Hi all.

Just set up a basic all grain brewing system at home and looking around for recipes to try out.

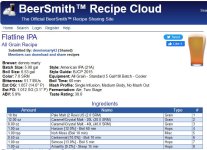

Are the recipe volumes listed on the BeerSmith website in US or UK gallons? The difference between the two units is about 20%.

Cheers

Peter

Just set up a basic all grain brewing system at home and looking around for recipes to try out.

Are the recipe volumes listed on the BeerSmith website in US or UK gallons? The difference between the two units is about 20%.

Cheers

Peter