This week I take a look at “dry hop creep”, what it is, how it affects beer and how to prevent it. This is my second article on the topic, and you can find the earlier article on dry hop creep here.

What is Dry Hop Creep?

At the basic level, dry hop creep is the continuation of fermentation in the bottle or keg after the beer has been finished and packaged for distribution. It primarily occurs in beers using very high levels of dry hopping which is why the term “dry hop creep” was coined.

Symptoms of dry hop creep include over-carbonation of bottles and kegs, over attenuation of the beer and often diacetyl (buttered popcorn flavor) as an off flavor in the finished beer. It is a potential problem for any unpasteurized of unfiltered packaged beer as these beers still contain active yeast cells.

Fermentation in the finished beer can result in a 1-2 plato drop in gravity over a period of 30-45 days along with a 5% increase in carbonation. This can be a serious issue for commercial beers.

Dry Hop Creep Research

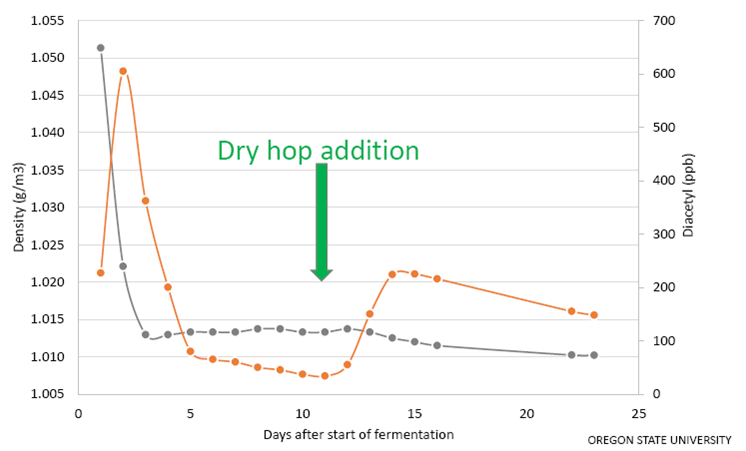

The chart at the top of this article shows dry hop creep (click on it to expand) and how it progresses over time. For several years now, craft brewers of IPAs with high levels of dry hopping have known about stability issues with their finished beer including the diacetyl off flavor.

However not until 2018 were researchers able to explain the problem in some detail. Oregon State University published a paper in the Journal of Agriculture and Food Chemistry and also presentations were made by Caolan Vaughan at Brewcon 2018 in Sydney and another was done at the Oregon Beer Summit.

The chart above is also from Oregon State University. As you can see the hop creep usually starts several days after the dry hop addition, and will continue to slowly ferment for up to 45 days. It also creates a significant spike (orange line) in diacetyl in the finished beer.

What Can Be Done About Dry Hop Creep?

There are several techniques available to pro and home brewers to reduce the impact of dry hop creep:

- Filter or Pasteurize the Finished Beer – Really the only way to completely eliminate hop creep, filtering or pasteurizing will remove live yeast from the equation, stopping further fermentation.

- Reduce Dry Hop Levels – Shift some dry hops to the whirlpool (before fermentation) where they are less likely to create enzyme problems.

- Cold Store you Beer – Hop creep is temperature dependent, and if you can ensure that the finished beer is stored cold, it will significantly reduce the enzyme and fermentation activity. However this is often difficult to assure once the beer leaves the brewery.

- Design “Creep” into the Recipe/Process – Some brewers purposely under-attenuate and also under-carbonate their beers, assuming hop creep will occur in finished bottles/kegs. While this won’t solve potential diacetyl issues, it can help with over-carbonated/over-attenuated beers. It can be difficult to determine how much “creep” to expect however.

- Dry Hop Earlier – Though not much reasearch has been done on this, some brewers believe dry hopping closer to fermentation will give the hop enzymes and yeast time to act before the beer is packaged, reducing the scope of the hop creep problem.

- Use Sulfites/Sulfates to Reduce Yeast Activity – While not an option for naturally conditioned bottles, you can consider adding potassium metabisulfite (and possibly potassium sorbate) to kegs to inhibit further fermentation. These additives are widely used in the wine/mead industry as a preservative and also to inhibit further fermentation.

- Use Enzymes to stop possible fermentation – There are some enzymes that can be added to inhibit VDKs that are active during hop creep and also inhibit diacetyl. These are called ADLC (Alpha Acetolactate Decarboxylase) enzymes. At the homebrew level there is CellarScience ADLC and also Murphy and Sons.

I hope you enjoyed this week’s article on hop creep. Thank you for joining me this week on the BeersSmith blog – please subscribe to the newsletter or listen to my video podcast for more great material on homebrewing.

Related Beer Brewing Articles from BeerSmith:

- Dry Hop Creep, Over-Carbonation and Diacetyl in Beer

- Diacetyl in Home Brewed Beer – The Butterscotch Flavor

- Four Tips for Avoiding Off Flavors in Home Brewed Beer

- Sour Beer Alternatives for Home Brewers – Part 2: Traditional Sours

- Brewing Gluten Free and Gluten Reduced Beer

- How Yeast Ferments Beer Over Time

- How to Make Hard Cider – The Easy Way

- Carbonation Options for Your Home Brewed Beer

Don't make another bad batch of beer! Give BeerSmith a try - you'll brew your best beer ever.

Download a free 21 day trial of BeerSmith now

{ 1 comment… read it below or add one }

This is a good discussion on an important topic for IPA brewers–thanks! One thing I would add as a easy and low-impact solution to this problem is to simply monitor the gravity following dry hopping to ensure that fermentation has ended before packaging the beer. Once the gravity has stabilized following dry hopping, also perform a forced diacetyl test (don’t skip this important step) to ensure the dry hop creep fermentation has cleaned up the diacetyl. In my experience, the dry hop creep fermentation has ended and diacetyl has been cleaned up within 1-2 weeks of dry hopping. When homebrewing, if I don’t feel like doing a diacetyl test, I just wait a 4-7 days after the dry hop creep fermentation is complete before packing (and I haven’t had diacetyl issues with this method).