This week I take a look at the hop cone and how its composition affects flavors when brewing beer.

Hop Cone Composition

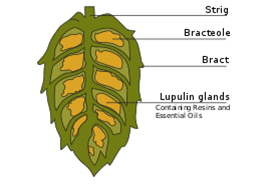

If we look at the hop cone image (upper right, Source: Stan Hieronymus) we can see the various parts of the hop cone. The bulk of the compounds we are interested in are in the lupulin glands which make up a small percentage of the cone.

The two major compounds we care about are alpha acids (humulones) which provide bitterness in the finished beer and aroma oils which provide the majority of the fresh hop aroma. However, hops are complex beasts and provide some 500 flavor compounds even though we tend to focus on the two mentioned above.

Most brewers work with pelletized hops, which are nothing more than diced and compressed hop cones. Taking a look at the average composition for a hop cone (source: Stan Hieronymus) by weight we have:

- Alpha Acids: 0-22%

- Aroma Oils: 0.5-4%

- Beta Acids: 0-10%

- Water: 10%

- Cellulose: 40-50%

- Pectin: 2%

- Lipids and Waxes: 5%

- Polyphenols: 2-5%

You can see that the bulk of the hop cone is made up of cellulose which is fibrous vegetal material that makes up the cells. Next is residual water which is about 10%. Next is alpha acids, which are the bittering acids in hops, and are typically in the 5-15% range for most hops. Polyphenols, which provide structure and head retention to the beer run from 2-5%. Lipids and waxes make up about 5% and pectin 2%.

Interestingly aroma oils which are the focus of most IPA brewers make up a tiny 0.5-4% of the total weight of the hop cone combined. This includes the list of typical aroma oils like myrcene, geraniol, linalool, etc… These compounds are the focus of both whirlpool hop and dry hop methods where we attempt to infuse aroma oils from the hop cone into the wort or beer without picking up too much of the vegetal notes from the hop cone itself.

The realization that alpha acids and aroma oils are only in a tiny portion of the cone leads to many of the concentrated hop products entering the market today. CO2 hop extracts are basically distilled alpha acids extracted from the luplin gland, and can be used as a replacement for bittering hops by boiling to isomerize the acids. Hop extract can also be stored for many years, which makes it a great way to preserve bittering hops commercially. You can also purchase isomerized hop extract, which is an extract that has been heated to isomerize it into bittering compounds. This type of extract can be added directly to the finished beer to adjust bitterness “to taste”.

Luplin powder (Cryo hops) is an extract also from the luplin gland but with an emphasis on preserving aroma oils. It is best used in dry and whirlpool hopping. Then there are the newest aroma oil extracts which come in two varieties. One isolates individual aroma oil compounds like myrcene, linalool, etc.., while the other type isolates oils from a particular hop variety. These also can be added to the finished beer “to taste”.

All of these new products are exciting, but they are also more expensive than hop pellets, so one has to consider the cost/benefit. At a homebrew scale where costs are less of a consideration they provide some excellent opportunities to try new things and even correct beers you have already brewed that may be imbalanced or lack proper aroma.

I hope you enjoyed this week’s article from the BeerSmith Home Brewing Blog. Please subscribe for regular weekly delivery, and don’t hesitate to leave a comment or send this article to a friend.