This week I look at how to adjust the free sulfite levels in your mead, wine or cider to achieve good shelf stability.

Most commercial wines, meads and ciders have the words “contains sulfites” somewhere on the label. Sulfites, a name for Sulfer Dioxide (SO2), is a preservative that is widely used in winemaking and the food industry. It has antibacterial properties, reducing the risk of infection and refermentation. It also has antioxident properties which means it can help prevent oxidation of the beverage while in the bottle. It is typically added in the form of Potassium Metabisulfite which is available from most beer and wine supply stores.

Sulfites are generally considered harmless, but roughly 1% of the US population is sulfite sensitive. This includes people who suffer from severe asthma or have a sulfite allergy. About 5-10% of those with asthma also have a sulfite allergy. Though many prepackaged foods have sulfite levels several times that of wine, most wine makers try to minimize the level of sulfites used to avoid triggering those with allergies.

Any wine with sulfite levels above 10 ppm must be labeled with “contains sulfites”, and the maximum levels for sulfites in the EU are 210 ppm for white, 400 ppm for sweet, and 160 ppm for red wines. In the US the limit is 350 ppm.

The sulfite needed for a beverage varies by slightly pH, sweetness and type. Sulfite is added in the form of Potassium Metabisulfite, which you can purchase from most brewing and wine supply stores.

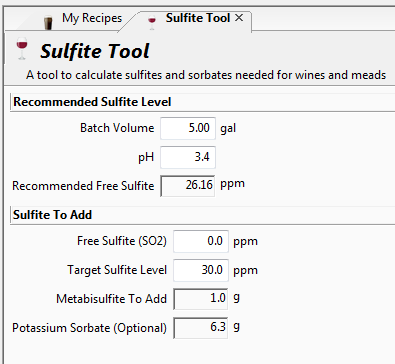

As a first order, you can estimate the minimum sulfite level needed from a pH reading of your wine, mead or cider using the Tools->Sulfite Tool in BeerSmith. Just enter the batch volume and measured pH and it will estimate the free sulfite level needed. This is your minimum target level based on an average wine.

You may want to target a slightly higher sulfite level depending on your beverage. For example white wines and ciders could use a slightly higher level in many cases. Sweet wines and sweet meads also generally need a bit more sulfite to help prevent secondary fermentation. Finally if you plan to backsweeten your cider or mead, I do recommend targeting a level much higher than the recommended level, again to prevent fermentation.

Note that the target level is expressed as “free sulfite”. This is the amount of free SO2 in the beverage, which may be different than the amount added as potassium metabisulfite earlier in the process. The reason for this is that if you add a given weight of potassium metabisulfite, some of the free SO2 will react with the beverage itself as well as any free oxygen in the beverage. So the resulting “free sulfite” level may be lower than expected.

To precisely hit a given target “free sulfite” level, many wine and mead makers use a sulfite test kit. Home wine, mead and cider makers can also purchase home versions of this kit. Using the kit you can estimate exactly how much free sulfite is in your beverage, and then make small additions to get to the target level you want. Again the Sulfite Tool in BeerSmith can help with this calculation. Simply enter the current measured Free sulfite level, your target level and batch volume and the program will estimate the amount of Potassium Metabisulfite to add. It also shows optional potassium sorbate if you plan to backsweeten your mead or cider.

In practice, I often will adjust my sulfite levels with a few additions. I will usually add the first sulfite addition once fermentation is completely done as a preservative during aging. As the mead or wine ages, I’ll make a second addition when I transfer for clearing and then take a final free sulfite measurement with my test kit and final addition shortly before bottling.

Hopefully you enjoyed this article on sulfites in mead, wine and cider. Thank you for joining me this week on the BeerSmith blog – please subscribe to the newsletter or listen to my video podcast for more great material on homebrewing.