This week I take a look at the differences between alpha and beta amylase which act during the mash to convert longer starch chains to simple sugars in beer.

Alpha vs Beta Amylase

Enzymes are naturally produced in malted barley during the malting process. Chief among these are alpha amylase and beta amylase. They are available in higher quantities in lighter colored base malts, and the base malted barley in your grain bill provides the bulk of the enzymes used in the mash.

These enzymes break down longer starch molecules into simpler sugar molecules that can be consumed by yeast during fermentation. As a side note, amylase also is naturally present in saliva and helps to sweeten some starches as you eat them. Alpha amylase is a common digestive enzyme, while beta amylase is associated with seed germination (during malting) and also fruit ripening.

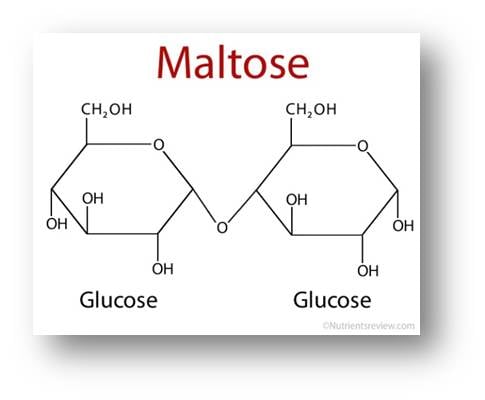

Beta amylase is arguably the main producer of fermentable sugars. It chops maltose molecules from the non-reducing end of a starch chain. It is effective at breaking down both amylose and amylopectin and also limits dextrines which effectively reduces the body of the beer. It is most active in the lower mash temperature range of 60-65C (140-149F), and also the low pH range of 5.1-5.3.

Alpha amylase has high concentrations in pale malt and especially 6 row barleys. It chops molecules randomly into longer glucose chains, and is also effective on amylose and amylopectins. Because alpha amylase chops randomly, it can create unfermentable dextrins as well as shorter fermentables like maltose. It reaches peak activity at a higher temperature around 70C (158F) and a pH of 5.3-5.7.

Temperature and Mash pH Strategies

Because alpha and beta amylase are most active in different temperature ranges and also different pH ranges, you can alter the mash pH and temperature of the main conversion step to achieve different results.

I covered the major strategies you can use in a more detailed article here which I highly recommend reading. That article covers the four major mash temperature strategies and also how you can target different mash pH ranges to achieve a particular result in the beer.

Thanks for joining me on the BeerSmith Home Brewing Blog. Be sure to sign up for my newsletter or my podcast (also on itunes…and youtube) for more great tips on homebrewing.