This week, I take a look at how to calculate the appropriate starter size for home brewing beer with liquid yeast. In part 1 of this in-depth series on yeast, I covered how you can calculate the required pitching rate (number of yeast cells needed) for a given batch of beer, understanding the viability of yeast over time, and also how to hydrate and use dry yeast. This week, I’ll finish the detailed calculations for liquid yeast as well as provide a summary on how to do the entire end-to-end calculation.

When We Last Left Our Yeast…

When We Last Left Our Yeast…

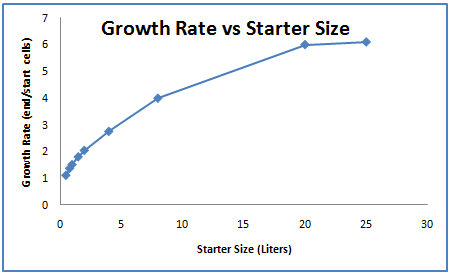

I ended part 1 on yeast starters explaining that all liquid starters are not created equally. The growth rate of the yeast (number of ending cells divided by the number of starting cells) varies depending on the pitching rate of the yeast. In fact if we pitch a typical liquid yeast package (vial or large smack pack) of 100 billion cells into starters of varying size we get the graph to the right. This is extracted from “Yeast, A Practical Guide” by Chris White and Jamil Zainasheff.

What this shows is that 100 billion cells pitched into a 2 liter starter will only grow to a bit over 200 billion cells (growth rate of 2.05), while the same 100 billion cells in a 20 liter (5+ gallon) starter will grow to about 600 billion cells (growth rate of 6.0). However, a 20 liter starter is essentially no starter at all if your batch of beer is only 20 liters.

In part 1, I covered how to calculate the ideal number of cells needed for an average batch of beer. A sample 5.25 gallon ale at 1.048 gravity needed about 177 billion yeast cells. So using the graph at the right, a 100 billion cell packet pitched into a starter of just over a liter would be sufficient for this beer. However, if we factor in viability (the aging of the yeast which was also covered in part 1), a larger starter of 2-3 liters is needed, since we won’t be starting with a fully viable 100 billion cell yeast package.

Since you don’t want your starter to be so huge it is a major fraction of your beer, the practical range most home brewers operate in is really on the left end of this graph – typically 1-4 liters for a five gallon batch. This means that in most cases, you will not achieve a growth rate above 3.0 for your starter unless you use a multi-stage starter.

Yeast Growth vs Starting Population

Yeast Growth vs Starting Population

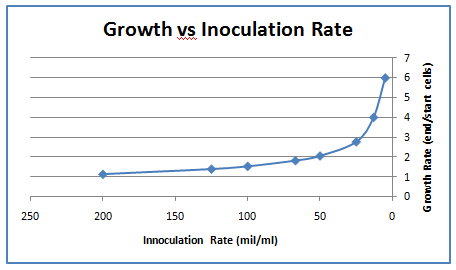

The above graph is great if you always pitch a 100 billion cell starter and are always brewing a 5.25 gallon batch, but often this is not the case. To generalize the above graph, we need to use it with larger or smaller starters and batch sizes.

It turns out this is not hard to do – since yeast growth depends primarily on the starting population and amount of wort available. To calculate starter size for the generic case we need to introduce a new term called the “inoculation rate”.

The amount of yeast per unit volume you start with is called the “inoculation rate”. Inoculation rate is typically expressed as millions of cells per milliliter of wort. For example, a 100 billion cell yeast pack in 2 liters of wort would work out to 50 mil/ml (50 million cells per milliliter). Inoculation rate is really easy to calculate, since you just take the starting number of cells and divide by the size of your starter. The math gets easy when you realize that 1 billion cells into a liter is the same as 1 million cells per milliliter.

So if we look at growth as a function of inoculation rate (see graph), we can see the same effect as described earlier – high growth only occurs in starters with relatively low inoculation rates. Since most homebrewers are using a 100 billion cell starter in 1-4 liters of wort (inoculation rates above 25 mil/ml) – we’re basically working on the left end of the graph at growth rates below 3.

How Many Yeast Packets Do I Need?

In practice, very large starters are often not desirable for the homebrewer so often you need to start with more than one vial/pack of liquid yeast in a batch. Doing this limits the growth rate needed so you don’t end up with a starter that is almost as big as your beer batch itself.

For example, lets look at making the same 5 gallon batch from a single small size (not the large one) Wyeast smack pack. Assuming the package is new (100% viable with 18 billion cells), the 5 gallon batch which we calculated needed 177 billion cells would give us a growth rate of 177/18 = 9.83. No matter how large a single starter is we are not going to get a growth factor greater than 6.0.

The alternative is to use two small smack packs in the starter which gives us 177/(2*18) = 4.91 growth. However, this is still a huge starter – since looking up a 4.91 growth on the chart gives us a starter size of nearly 4 gallons (15 liters) to make a 5 gallon beer. Clearly this won’t work either.

In practice, you need to limit the growth of the starter generally to less than a factor of 3.0 so you don’t make a starter that is almost as large as your finished beer. You can do this by upping the number of packets each time your required growth goes over 3.0. So in the above example, moving to three small smack packs gives us a required growth of 177/(3*18) = 3.2 growth and four small smack packs gives 177/(4*18) = 2.45 growth. So four small packets would be needed with (from the chart) a starter of approximately 3.5 liters.

Knowing this now, its usually best to calculate the number of packets first, adjusting the growth rate needed, and then calculating the actual starter size.

Putting it All Together – How to Calculate Liquid Yeast Starter Size

Here’s a summary of the entire yeast starter calculation from end to end as a step-by-step process:

- Calculate the total number of yeast cells needed for your batch based on the starting gravity and volume of your batch. It is typically expressed in billions of cells – and recommended you pitch 0.75 million cells per milliliter per degree plato for ales, 1.5 mil/ml-P for lagers and 1.0 mil/ml-P for hybrids. If you are not used to working in plato and milliliters, the english equivalents would be (approximately): 0.71 billion cells per gallon per point of specific gravity for an ale, 1.42 bil/gal-point for a lager and 0.948 bil/gal-point for a hybrid. A sample 1.050 gravity, beer would have 50 gravity points and for a 5 gallon batch need -> 1.42 x 50 x 5= 355 billion cells.

- Calculate the Viability of Your Yeast Packs – As covered in part 1, Wyeast and White labs large tubes/packs have a little over 100 billion cells when new, and the small Wyeast pack has about 18-20 billion cells. However, these packages lose about 20% of their cells per month of aging. So a 100 billion pack/vial would only have about half of its cells (51 billion) viable after three months.

- Calculate the Growth Rate Needed – Divide the total number of yeast cells needed by the number of viable cells in your yeast pack. So if you are brewing the lager mentioned above which needs 355 billion cells from a single pack of yeast that is one month old (which has about 80 billion cells), the growth rate needed is 355/80 which is 4.4.

- Decide if You Need More Packs or a Multi-Step Starter – If you need to achieve a growth rate above 3.0, it is probably time to look at adding more yeast packs to your starter or creating a multi-step starter. The reason is that beyond a growth rate of 3.0, the starter sizes start to get very large relative to the size of your batch of beer. In the example we just mentioned (growth rate of 4.4) you would need to have a starter of well over 10 liters (almost 3 gallons) to get that growth level in our 5 gallon batch. Buying a second yeast pack would cut the growth rate needed down to a more manageable level of 2.2.

- Look Up the Innoculation Rate – Now that we know the growth rate needed, and have adjusted it down a bit (to less than 3.0) if needed, we can determine what our initial inoculation rate should be. The easy way to do this is by looking at the graph above and work backwards. Find your desired growth rate on the Y axis, and then look up the needed inoculation rate on the X axis. For example if we need a growth rate of 2.2, the inoculation rate is approximately 50 mil/ml.

- Find the Starter Size – Since we know how many total yeast cells we are using for our starter based on the viability and number of yeast packs, and we have the inoculation rate, we can just divide the two to get the starter size. Divide the number of viable cells in your yeast pack by the inoculation rate to get the starter size. For the example we’ve been tracking, we decided in step 4 to use two starter yeast packs, each with 80 million viable cells for a total of 160 million cells. We found our inoculation rate from step 5 would be 50 mil/ml (which is also 50 billion cells/liter). Dividing the two we get 160/50 which is 3.2 liters – so a 3.2 liter starter is ideal here.

- Create the Starter – Once you have the size, you need only create the starter itself. An ideal starting gravity for your yeast starter is 1.036 (9 plato). To create the starter, just open BeerSmith (or your favorite tool), create a blank recipe with the starter size, and add enough dry malt extract to reach a starting gravity of 1.036 for your starter. If you don’t have the tool handy, a good rule of thumb is about 0.2 lb of dry malt extract per quart of starter (or 90 grams/liter).

The whole process is a bit complex, which is why I’ve added a separate calculator to the upcoming version of BeerSmith to make it much easier. Thank you for joining me on the BeerSmith Home Brewing Blog – I hope you will subscribe for more great articles, and have a great week!

So I have a question, the growth rate is affected by more than just the starter size. I have access to a temperature controlled shaker and an autoclave so I grow my starters on that, I assume that a shaken starter will grow significantly faster than the average starter. My question is how much faster, I ask because I am too lazy to do cell counts.

Hi,

Yes I should have mentioned in the article that using a stir plate can increase your growth substantially – by a factor of about 2.0 to 2.5 if a stir plate is used. Note, however, that the growth is still limited by the overall amount of sugar so even with a stir plate it is hard to get a growth rate above 6.0.

Brad

Pingback: Tweets that mention Yeast Starters for Home Brewing Beer Part 2 | Home Brewing Beer Blog by BeerSmith -- Topsy.com

Question: could you please share the actual formulas you used to get those growth curves in Excel?

Thanks for a really great set of articles. I’ve typically done starters just cause I new I needed to, but never really understood the numbers. Question on the use of a stir plate though: If a stir plate increases growth by a factor of 2-2.5, does this mean that I should adjust the Growth Rate Needed by dividing the result by 2.25? Also, do you happen to have the raw data set that was used to create the Growth vs. Inoculation chart? Would be really helpful when trying to determine the Inoculation Rate.

Can’t wait till this is included in the BeerSmith program. Thanks again!

TJ

Hi,

The stir plate does increase growth by about 2.25. However, there is still a hard limit of about 6.0 growth rate overall due to lack of sugar to ferment. If you are using a stir plate you can essentially divide your growth by the factor.

Per your request and the earlier one I will try to attach a spreadsheet later this week. I don’t have a formula – the data was taken from Chris White’s yeast book.

Brad

I love this miniseries. This seems like this is everything I need to know to get started in the yeast business. Very informative!

I recently brewed my best beer ever – simply by making a very large starter – it makes all the difference in the world! My question after reading your excellent 2 part article is: … no one ever seems to mention re-pitching yeast and how to calculate the volume needed. I would presume one needs to keep track of the batch of beer and essentially treat it as a very large starter? … then by factoring in age; be able to determine the active cell count of the recovered yeast? Would it be possible to make this the topic of a third (and final) episode on yeast? This would be excellent and I think would be appreciated by many many home brewers trying to save a little money on yeast…. Sincerely, FloydSki 15 year home brewer.

Pingback: Multiple yeast packs for starter - Home Brew Forums

Pingback: Pitching rate with harvested commercial yeast - Home Brew Forums

Pingback: Beersmith 2.0 question - Home Brew Forums

Thanks for the very good information in those article. My question is about what we do with the starter next. We started using starter lately, but we realized that adding a 5 liters starter to a 5 gallon batch dilute the beer a lot and change it’s final results. Is there an easy way to filter out the water from the starter and then only pitch the yeast in the beer ? Was is the best approach ?

About starter sizes. When finish, I always put the starter in the refrigerator 24h to collect the yeast, and then pour off most of the wort before mixing and pitching into the beer. That way you can make big starters without adding to much volume and undesirable tast from the wort in the starter. Everytime, I collect some of the starter for storage before chilling it down and use that for the next starter. Works well, at least 5-6 times.

Pingback: Yeast starter or smack pack adequate? - Page 3 - Home Brew Forums

My finished batch size into the fermenter is ~16 gallons. I use a single starter into multiple starters to take one smack pack up; hopefully, to around the count I need, let’s say around 750 billion cells. Can BeerSmith help me, and if so how, to keep track of multi-stage starters to better estimate the cell count into the fermenter?

“Question: could you please share the actual formulas you used to get those growth curves in Excel?”

After doing a non-linear regression on the data points, it turns out (with some margin of error) that the function for calculating starter volume (y) via growth rate (x) is approximately

y = 1.647631996 ^ x

I have three questions.

First, the articles both mention starter volume, but neither specifies the gravity of the wort. Surely this must affect the growth rate of the yeast. What is the starter gravity at which the curve is valid? And how would changing the gravity alter the growth rate?

Second, when doing a multistage starter, what is the procedure? Do you just add more wort, or do you let the yeast settle out and pour off the clear liquid before adding more wort? How do either of these procedures affect the yeast growth? And would the second procedure significantly tend to select the more flocculent yeast cells from the population?

Third, is there any practical way to actually measure an accurate estimate of the yeast cell concentration, without having a lot of laboratory equipment or procedures such as a microscope and special slides, and methods of measuring out tiny fractions of a milliliter? This would give some feedback as to whether the calculations described in the article are actually correct. It seems to me that there are a number of unstated assumptions that enter the calculations, such as storage and fermentation temperatures, duration and degree of agitation with a stir plate, and amount of oxygen in the wort.

I am a newby to this and am having a good time with it. The question. I used a starter for my last two batches without any of the afore given information. They were both about 1500 ml in volume. After pitching into well oxygenated wert I got almost explosive growth and foaming during the first 12 to 18 hours of primary fermentation. The first batch blew the stopper out of the 6 gallon glass fermenter. The second covered the top of the fermenter and the large bore relief tube for about half of its 4 foot length with foam. Is this normal ? Neither beer had any bad effects that could be tasted by myself or several other brewers.

I wonder how BUD/ COORS feels about all of this brewing going on?

Did I miss it or is there no mention of fermentation time in this article? E.g. How long do you need to ferment the starter to get the stated growth rate?

I would think it varies with starter size. It would take longer to ferment all the sugar in a large starter vs a small starter.

Pingback: Brewing a White Stout | Filament

OK. If a 20 L starter under ideal conditions will allow the yeast to multiply up to the max growth rate of 6, turning a 100 billion cell count into 600 billion cells (Quote: “100 billion cells in a 20 liter (5+ gallon) starter will grow to about 600 billion cells (growth rate of 6.0)”); isn’t it safe to assume the yeast will do the same in a batch of 5.25 gallons (20 L), and reach more than the required amount of cells within the first hours of reproduction? Why is then a starter required if theoretically it would be the same as pitching the original smack pack into our wort where the yeast will happily reproduce as long as it has enough oxygen to do so? Please forgive my ignorance but I am new to home-brewing and want to look cool when my wife questions the mess I made in the kitchen with a starter.

You are correct – you could pitch a smaller than recommended amount of yeast into a batch (lots of brewers do it) and grow them in the batch. The ideal pitch rates, however, put less stress on the yeast and reduce the incidence of off flavors in the finished beer which is why most brewers try to target the ideal pitch rates.

If your sanitary practices are good, then you can use less yeast. If you can even control the temperature during fermentation that also helps. You will lose time, however. As much as 2 days even. So if you are making a starter anyway, use an ample size. Is that the gist of it?

I’m a home brewer moving into professional brewing. Our brewery will be utilizing a 10 BBl and a 1 BBl pilot system. We have a lab set up and doing viability/cell counts for pitching our pilot system which we have just started. My question is: will there be a slurry function in future updates that we could enter our cell density, viability to calculate the volume/weight of slurry we would need for a given beer? I calculate by hand now which isn’t a problem but having this kind of functionality in Beersmith would be very nice.

Cheers!

I’ll say it again..beginners..you don’t have to pitch immediately! It’s easier (and better in some cases) to ferment out the starter (24-36 hours, however long it takes) and then chill..chill for as long as it takes for the yeast to settle completely, then you can pour off nearly all the starter liquid! That way it doesn’t dilute your brew or introduce any off flavors. (Someone said be sure to taste your starter) also, there’s a theory that by allowing it to really settle, you are keeping the late yeast cell population that hangs out for fully attenuating, which is good advice for not pouring off the excess too early before chilling and settling.